盛興鋼品代理River Clack產品,觀迎詢問..

原廠型錄摘要如下:

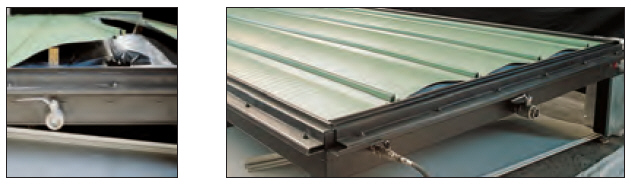

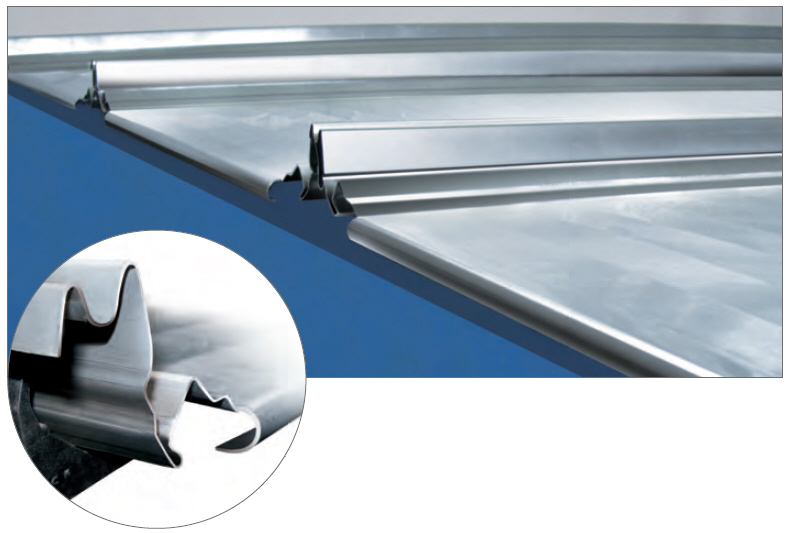

The system is characterized by an exceptional ease of installation, with no sealants, gaskets or through perforations. Fasten system is made by reinforced polyamide brackets to be placed along each spacer. They allow free thermal movement preventing in the same time thermal bridges or electro corrosion between RIVERCLACK and the below structure.

The system is installed using simple foot pressure onto the purpose designed polyamide bracket fixed to the spacer by two screws.

RIVERCLACK sheet installation in 6 steps.

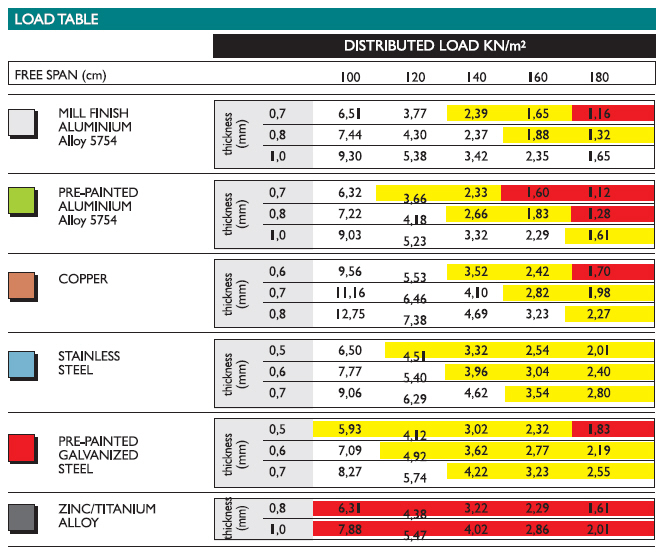

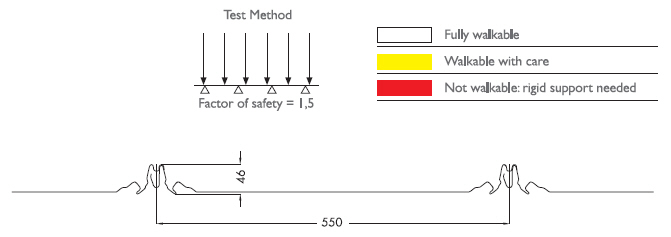

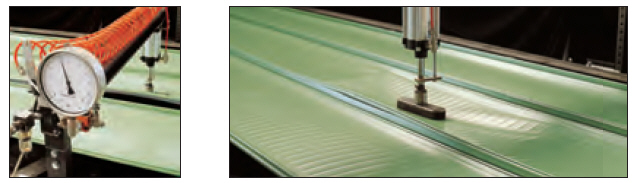

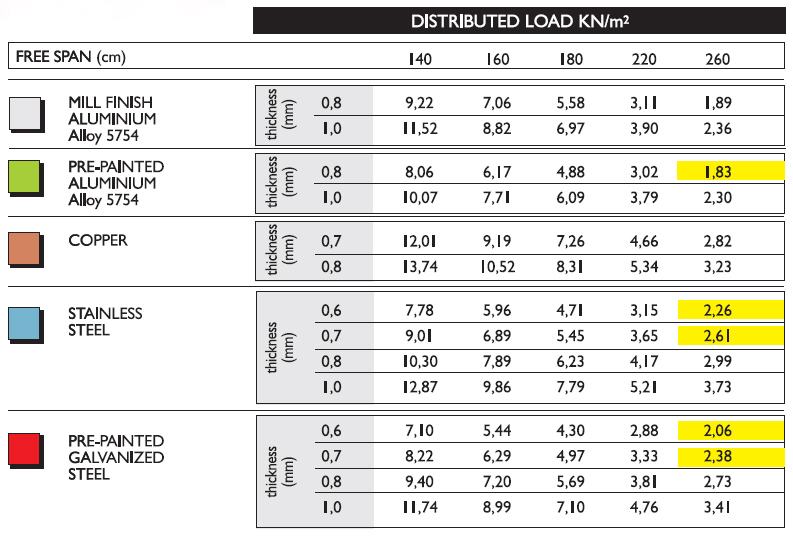

WALK-ABILITY

Load tests have been carried out on a 0.7 mm thick aluminium RIVERCLACK sheet using a rubber-clad piston designed to simulate human foot traffic.Both dynamic and static-dynamic tests have demonstrated product high performances. RIVERCLACK roof system can be safety and fully walked up and down.

WATERPROOFING

The test has been carried on 19.50 m long 0.7 thick aluminium sheets laid down with a 0.3% slope; using the sheets as the base of a pool filled with water, after 45 days, only a few drips have been detected from the draining joint. No leaks in roof intrados have been found; moreover, also bottom was entirely dry.Therefore, RIVERCLACK system guarantees full waterproofing.

WIND SUCTION LOAD RESISTANCE

Wind resistance test has been performed on 0.7 mm thick aluminium sheets and at 1200 mm span.

A purpose designed plastic airbag has been progressively inflated under the sheets to generate an underneath pressure and simulate the effects of a wind vortex passing over the roof, till to requested loads. The achieved results are the demonstration of the roof system excellent performances, even in strong gusts of wind, till more than 700 daN/m2.

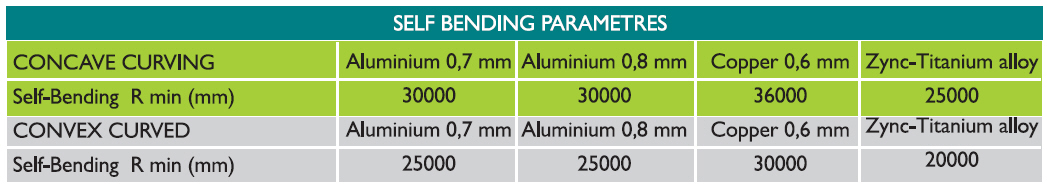

CURVING

RIVERCLACK sheets are extremely flexible. They are self-bending on convex, concave and S shapes, depending on material and thickness used, according to the below table:

Beyond the above-cited limits, sheets must be mechanically curved.

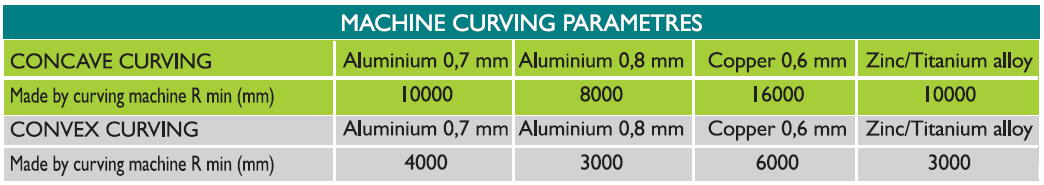

MACHINE CURVING

Machine curving is available to make RIVERCLACK meet the nowadays architectural trends of convex, concave and S shapes, keeping constant and unaltered its highest standards of reliability and long life.

The machine curving process can be carried out in the factory as well as on site thus allowing to curve, partially or in total, long sheets

Machine curving limitations according to different materials and thickness are described in the below table:

DOUBLE CURVING

The so-called double curving occurs when spherical and hemi-spherical structures need to be covered; it also involves structures which have been planned curved both in the direction of the sheet axis and in its normal direction. It appears also in case of a curving together with the need of tapering.

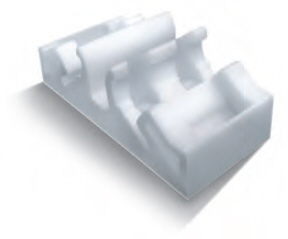

In order to accomodate this, besides the development of suitable analysis software, Iscom has designed a special friction-proof bracket in-width adjustable, capable of absorbing the differences resulting between one sheet and the next. It is always advisable to contact Iscom technical offices to perform the feasibility analysis of these applications.

TAPERED SHEETS

RIVERCLACK new generation rolling mills can be equipped with a special kit which allows to produce tapered or custom width panels in order to comply with conic or “fan” shaped roof geometries.

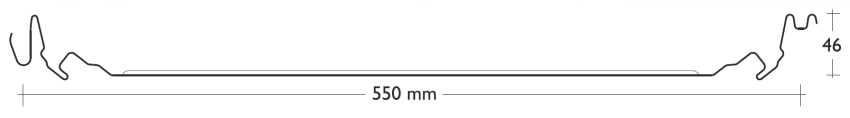

HIGH SEAM-RIVERCLACK 50

In case of large span distance, ISCOM can provide a special version of the Riverclack profile: Riverclack 50

The high seam profile RIVERCLACK 50, being characterized by a rib’s high of 70mm instead of 46mm, allows to span up to more than 2 metres, keeping unchanged all the typical features of RIVERCLACK such as fixing system, drainage channel, custom lengths and improving both the mechanical performance and the hydraulic capacity of the profile.

“TORO” END LAP

The sheets end lap, renewed and improved with the so called “Toro” add some extra features to the RIVERCLACK system:

It strengthens the “gutter side lap” of the sheet

It helps the drainage, avoiding risks of water dripping outside the gutter.

It confers a high aesthetic value, enhancing sheets final section.

It avoids the manual bending of the sheets end lap during the installation phase,

which is required for slopes lower than 5%.

“Toro” end lap is for both sheet’s ends, bringing the following advantages:

.Possibility to employ the RIVERCLACK system on roofs from gutter to gutter with the same features in both terminals.

.No constraints as for direction of installation.

.Improved ridge detailing thanks to the strengthening of the end lap.

The “Toro” is available only for RIVERCLACK 55 sheets.

In any case “Toro” is not available for tapered, curved and bended sheets.