The profile shaping system QUADRO-KS has all the feature of the QUADRO system. The unit uses the same cartridges to produce the desired profiles. This system is equipped with a slitter for longitudinal cuts.

The adjustable side of the machine can be set to the angle required for slanted panels or standing seam sheets. The required angle is calculated by means of the touch-panel. For this purpose the 3 dimensions of the plate are required, i.e. narrow-wide-long. Irrespective of the form of the profile, a single operation feeds the strip, cuts it obliquely and shapes the profile.

Electro hydraulic operation, for mounting on the QUADRO profile shaping machine. The notching unit is installed in front of the QUADRO profile shaping machine. The notching operation is programmed into the controller of the profile shaping system and included in the production process. Tool supports are mounted on a flanged unit with a hydraulic sub-assembly that is connected to the QUADRO controller.

The basic configuration contains a tool set to notch Sofit panels(reveal panels). Tool sets are available and may be exchanged for other, specified forms and profiles. Tool sets can be produced in accordance with customer requirements. For special notching processes the AK-QUAD can also be operated as a stand-alone notching machine. With the appropriate tool sets, applications range from rhombuses, shingles or coffered roof slabs.

The STA is mounted in the out-feed area of the QUADRO. Profiled strips that were previously notched by an AKQUAD in the profile area may be cut at angles ranging from -60°to +60°

When the profiled and notched strip reaches the programmed final position, the table is manually tilted to the respective angle and the profiled strip is clamped by means of the manually operated hold-down. Next the strip is cut with a manually operated roller shear.

Notching Unit

Profile shaping system QUADRO-KS

The profile shaping system QUADRO-KS has all the feature of the QUADRO system. The unit uses the same cartridges to produce the desired profiles. This system is equipped with a slitter for longitudinal cuts. The adjustable side of the machine can be set to the angle required for slanted panels or standing seam sheets. The required angle is calculated by means of the touch-panel. For this purpose the 3 dimensions of the plate are required, i.e. narrow-wide-long. Irrespective of the form of the profile, a single operation feeds the strip, cuts it obliquely and shapes the profile.

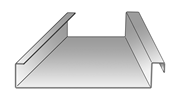

Quadro roof profiles with profiled surface.

A special profile shaping system in combination with the QUADRO can produce different forms of surface profiling to stabilize the surfaces for increased rafter distances.

Notching unit AK-QUAD

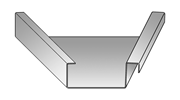

Possible shapes for rhombic notching

| Max. notching size | 50x100mm | Stainless steel | up to 0.5 mm |

| Non-ferrous metal | up to 1.0mm | Dimensions | 900x1650x1300 mm |

| Sheet steel | up to 0.8mm | Electrical connection | 400V, 50Hz |

Oblique cutting machine STA

| Ferrous metals | ≤ 400 N/mm2,0.5 ~ 0.7 | Dimensions | L x W x H | |

| Non-ferrous metals | ≤ 400 N/mm2 ,0.6 ~ 0.8 | 1,700 x 2,100 x 1,300 mm | ||

| Stainless steel | ≤ 700 N/mm2 ,0.4 ~ 0.5 | Weight | app. 285 kg (STA) / apps 315 kg (STA-M) |

Oblique cutting machine STA-M

Same construction as the basic machine STA, however, this is equipped with a motorized roller shear.

Oblique cutting machine STA-MS

Same construction as the basic machine STA, however, this is equipped with a motorized roller shear and a fully automatic pivoting device.