SPA/PAC: Profile shaping machine SPM-KS/PMC-KS

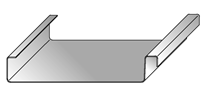

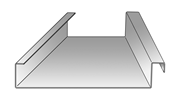

The profile shaping machine SPM-KS for standing seam profiles or PMC-KS for standing seam profiles with Clip Relief is designed for the following operations:

• Profiling of parallel panels

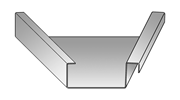

• Cutting conical panels and profile shaping on both sides in a single operation

• Cutting conical panels and one side profile shaping in a single operation

• Profile shaping of previously oblique cut plates in a single operation

The adjustable side of the machine can be set to the angle required for slanted panels or standing seam sheets

The basic equipment supplied includes:

• Electrically powered roller shears to perform cross cuts, cutting is initiated automatically

• Slitters with roller shear

• Strip intake with clutch

• Electronic length measurement in mm

• Position control for fully automatic operation with 25 programs for quantity and selections of lengths,

to calculate the setting points for oblique cuts and profile shaping

• The profile shaping operation of parallel panels may be executed in single cycle as well as continuous

cycle mode

• Profile shaping of slanted plates is only available in single cycle mode

The lay direction of the panels determines whether cutting and profile shaping occurs from narrow to wide or from wide to narrow plate widths. The maximum slitting angle is limited to 3∘. The intake width is adjustable from 300-800mm.

A special version caters for a profile height of 32 mm and/or an intake width of 1000mm.

Available options :

| Technical data | SPM-KS | PMC-KS | Unit | |

| LxWxH | 1890x1700x1170 | 2140x1700x1170 | mm | |

| Weight | 850 | 910 | kg | |

| Operating speed | app. 11 | app. 11 | m/min | |

| Drive | Power | 2x0.55 | kw | |

| Voltage | 400 | Volt. | ||

| Phase | 3 | phase | ||

| Shaping stages | 7 | 9 | roller stations | |